Power Take Off, commonly referred to as PTO, is a mechanical power transfer system used in heavy-duty vehicles, trucks, tractors, industrial machinery, trailers, and construction equipment. A PTO allows the engine's power to be redirected to auxiliary equipment such as hydraulic pumps, tipping systems, compressors, sweepers, winches, or water pumps — enabling the vehicle to perform additional functions beyond movement.

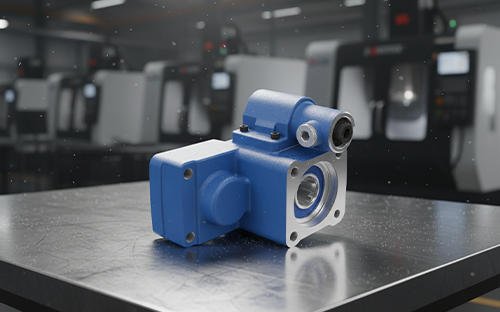

Power Take Off (PTO) is a mechanical output connection mounted on the transmission or engine, designed to transfer rotational power to external systems. In many industries, PTO is also known as an auxiliary gearbox. The purpose of a PTO is to convert engine-generated motion into usable power for machinery or hydraulic systems, making the vehicle more versatile and functional.

A PTO works by connecting directly to the vehicle’s transmission system. When activated, the PTO engages gears that transfer the engine’s rotational force to a hydraulic pump or similar external device.

This mechanism allows:

Redirection of engine power to auxiliary equipment

Controlled and stable power output

Continuous operation without the need for an additional engine

With PTO engagement, the vehicle can lift loads, pump fluids, operate hydraulic arms, or drive rotating mechanical systems with efficiency and stability.

PTO systems are widely used across multiple industries and applications, including:

Tipper trucks and trailer lifting systems

Tractors and agricultural equipment

Cranes and recovery vehicles

Fire trucks and water pumping systems

Road sweeping and municipal cleaning vehicles

Industrial compressors and hydraulic press systems

In any machinery where external power is required from the main engine, a Power Take Off system is essential.

Different industries use various types of PTO designs depending on operating needs and required torque levels:

Mechanical PTO

Pneumatic PTO

Hydraulic PTO

Each type has its advantages depending on the level of control, automation, and power output needed.

PTO pricing varies depending on several factors such as:

Vehicle brand and transmission compatibility

Type of PTO system

Torque and power capacity

Manufacturing quality and certification standards

Local or imported production

High-quality PTO systems typically provide longer service life, reduce maintenance costs, and ensure reliable operational performance.

Choosing the correct PTO system is critical. Before purchasing, the following factors should be evaluated:

Compatibility with the vehicle transmission

Required torque and horsepower

Application type (tipping system, hydraulic pump, crane, compressor, etc.)

Availability of spare parts and technical support

Warranty and durability expectations

Selecting the wrong PTO can lead to poor performance, overheating, power loss, and costly mechanical failures.