In modern industry, agriculture, and heavy machinery, the hydraulic pump is one of the most essential components. Acting as the power source of hydraulic systems, a hydraulic pump converts mechanical energy into hydraulic energy by transmitting fluid under pressure. But what exactly is a hydraulic pump, how does it work, where is it used, and what determines hydraulic pump prices? Let’s explore in detail.

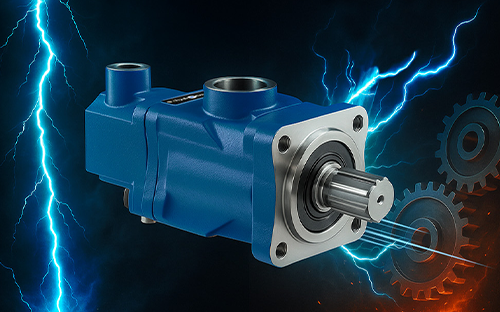

A hydraulic pump is a device that converts external mechanical energy (for example, from a motor or PTO) into hydraulic energy. Its working principle is simple: the pump draws hydraulic fluid from a reservoir and delivers it into the system under pressure. This pressurized fluid then powers hydraulic cylinders, motors, or valves.

The key function of a hydraulic pump is to provide a continuous and controlled flow of fluid. For this reason, hydraulic pumps must be durable, efficient, and reliable to ensure the overall performance of the system.

The applications of hydraulic pumps are vast and cover a wide range of industries. Common usage areas include:

Construction and heavy machinery: Excavators, loaders, dump trucks, cranes.

Agricultural equipment: Tractors, balers, irrigation systems, and other farming machinery.

Industry and manufacturing: Press machines, molding systems, industrial automation lines.

Transportation and logistics: Lifting systems in trucks, forklifts, and material handling equipment.

Energy sector: Hydraulic systems in hydroelectric plants and energy facilities.

In short, wherever controlled power and movement are required, a hydraulic pump is at work.

Depending on the application, there are several types of hydraulic pumps:

Gear pumps – Simple, durable, and cost-effective.

Piston pumps – Suitable for high-pressure applications.

Axial piston pumps – Compact design with high efficiency.

Vane pumps – Known for quiet operation.

Manufacturers like Hydrotime provide a wide range of hydraulic pumps tailored to different sectors and needs.

Hydraulic pump prices vary depending on several factors:

Pump type and capacity (gear pump, piston pump, axial piston pump, etc.)

Flow rate and pressure specifications

Brand reputation and manufacturing quality

Application and installation type

Local production or imported product

Generally, gear pumps are more affordable, while high-pressure piston and axial piston pumps are priced higher due to their advanced design. However, the key is not just the price—choosing the right hydraulic pump ensures long-term efficiency and reduces operational costs.

When purchasing a hydraulic pump, price alone should not be the deciding factor. Important considerations include:

The system’s required flow and pressure capacity

Pump durability and warranty coverage

Ease of installation and spare part availability

Energy efficiency and long service life

Trusted brands like Hydrotime provide certified quality, after-sales support, and reliable technical assistance—making them a preferred choice worldwide.

In summary, the hydraulic pump is the heart of hydraulic systems in today’s industries and heavy-duty equipment. A properly selected hydraulic pump not only delivers superior performance but also lowers long-term operating costs. By evaluating hydraulic pump prices, types, and your technical requirements, you can find the most suitable solution for your application.

Hydrotime hydraulic pumps combine durability, quality, and performance—making them the preferred choice in both domestic and international markets.

With the right hydraulic pump, your systems can achieve maximum efficiency and reliability.