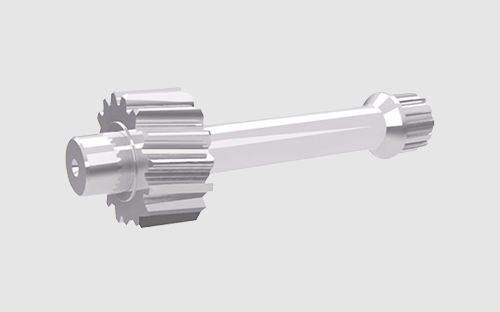

The Cardan shaft, also known as a drive shaft or propeller shaft, is one of the most important components used to transmit power in mechanical and automotive systems. Found in trucks, tractors, industrial machinery, and heavy-duty vehicles, the Cardan shaft ensures smooth torque transmission between moving or misaligned parts.

It plays a vital role in transferring engine or gearbox power efficiently, even under high load and angular displacement, providing both flexibility and durability in motion.

A Cardan shaft is a mechanical power transmission component that transfers rotational motion and torque from one shaft to another, even when the two shafts are not in perfect alignment.

At both ends of the Cardan shaft are universal joints (Cardan joints) that allow the shaft to operate at variable angles. This flexibility minimizes vibration and compensates for movement between the driving and driven components.

In simple terms, a Cardan shaft connects the engine or gearbox to another system (such as a differential, hydraulic pump, or industrial machine), allowing consistent power transfer under dynamic conditions.

The Cardan shaft operates based on the universal joint principle. The shaft transmits torque through joints that maintain constant rotation between two shafts with different angles.

When the engine generates torque, it is transmitted through the gearbox to the Cardan shaft, which delivers this power to the differential or driven machinery.

This system ensures:

Efficient power transfer over long distances.

Reduced vibration during operation.

Longer service life and system stability.

Thanks to its precision design, the Cardan shaft maintains mechanical balance and reduces power losses in motion systems.

Cardan shafts are used in a wide range of industrial and automotive applications, including:

Trucks and trailers – power transfer from the gearbox to the differential.

Agricultural machinery – in tractors, PTO drives, balers, and harvesting systems.

Construction equipment – in excavators, loaders, mixers, and cranes.

Industrial machinery – press machines, pumps, and production lines.

Marine and railway systems – in propulsion and power transmission applications.

In short, wherever flexible and reliable torque transmission is required, the Cardan shaft is indispensable.

Different Cardan shaft types are designed according to application and operational requirements:

Single joint Cardan shaft: used for short distances and low angles.

Double joint Cardan shaft: ideal for systems requiring higher angular flexibility.

Telescopic Cardan shaft: adjustable length design for systems with variable distances.

Heavy-duty industrial Cardan shaft: designed for continuous operation and high torque loads.

Hydrotime and other leading manufacturers produce precision-balanced Cardan shafts tailored for various industries and operating conditions.

Cardan shaft prices vary based on several factors:

Length and torque capacity of the shaft

Material type (high-grade alloy steel, carbon steel, or special coatings)

Universal joint design (single, double, or telescopic)

Manufacturing quality and balance accuracy

Application field (automotive, agriculture, industry, etc.)

While lower-cost models may be suitable for light-duty applications, investing in a high-quality, balanced Cardan shaft ensures long-term durability, reduced maintenance, and superior performance.

Selecting the right Cardan shaft is crucial for achieving optimal system performance. Important factors to consider include:

Required torque and rotational speed

Angle of operation and shaft length

Material quality and surface treatment

Precision balancing and vibration control

After-sales support, spare parts, and warranty

A properly selected Cardan shaft minimizes vibration, prevents power loss, and extends the lifespan of the entire drive system.

To summarize, the Cardan shaft is a key mechanical component that enables efficient, reliable, and flexible power transmission between rotating parts.

Hydrotime manufactures high-quality Cardan shafts that meet international standards, offering excellent balance, long service life, and superior torque performance.

With the right Cardan shaft, your machinery or vehicles can achieve maximum efficiency, minimum vibration, and long-lasting reliability.